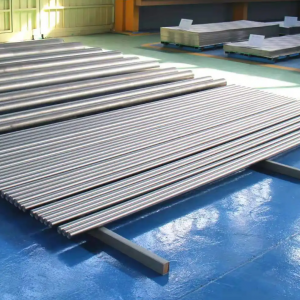

Superalloy InconelX-750/ UNS N07750/ AlloyX-750 Seamless Pipe, Sheet, Wire

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings

Production Standards

|

Product |

ASTM |

|

Bars and Forgings |

B 637 |

Chemical Composition

|

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

S |

Ti |

Nb+Ta |

Al |

Co |

Cu |

|

Min |

70.0

|

14.0 |

5.0 |

|

|

|

|

2.25 |

0.70 |

0.40 |

|

|

|

Max |

17.0 |

9.0 |

0.08 |

1.00 |

0.50 |

0.010 |

2.75 |

1.20 |

1.00 |

1.00 |

0.50 |

Physical Properties

|

Density |

8.28 g/cm3 |

|

Melting |

1393-1427℃ |

Inconel X-750 Features

Inconel X-750 alloy is mainly a nickel-based superalloy which is age-strengthened with γ[Ni3(Al, Ti, Nb)] phase. It has good corrosion resistance and oxidation resistance below 980℃, and below 800℃ It has high corrosion resistance. It has good relaxation resistance below 540°C, as well as good formability and weldability. This alloy is mainly used for the manufacture of aircraft engines that work below 800°C and require high strength. . Springs can also be used to manufacture steam turbine turbine blades and other parts, such as plates, strips, bars, forgings, rings, wires, pipes, etc.

Inconel X-750 Heat Treatment Process

The solution heat treatment system for plates, strips and pipes in the supply state is 980℃±15℃, air cooling. For the intermediate heat treatment system of materials and parts, the following processes can be selected for heat treatment.

Annealing: 955~1010℃, water cooling.

Annealing of welded parts before welding: 980℃, 1h.

Stress relief annealing of welded parts: 900℃, moisturizing for 2h.

Stress relief annealing: 885℃±15℃, 24h, air cooling.

Inconel X-750 Available Varieties and Specifications

Bars, forgings, rings, hot-rolled sheets, cold-rolled sheets, strips, tubes and wires can be supplied in various sizes.

Plates and strips are generally supplied after hot or cold rolling, annealing or solution, pickling and polishing.

Bars, forgings and rings can be supplied in the forged or hot rolled state; they can also be supplied in solution treatment after forging; bars can be supplied after solution and polished or turned, and can be supplied in cold when the order requires Pull state into place.

The wire can be supplied in the solid solution state; for the wire with a nominal diameter or thickness below 6.35mm, it can be solid solution and supplied with a cold drawing deformation of 50% to 65%; the nominal diameter or side length is greater than 6.35mm. Wire, after solution treatment, is supplied with a cold-drawing deformation of not less than 30%. For wires with a nominal diameter or side length not greater than 0.65mm, they can be supplied with a cold-drawing deformation of not less than 15% after solution treatment as required.

Inconel X-750 Application Areas

The alloy is mainly used for the manufacture of leaf springs and coil springs with high strength requirements and relaxation resistance for aero-engines operating below 800°C. It can also be used to make parts such as turbine blades. Available varieties are sheet, strip, bar, forging, ring, wire and tube.