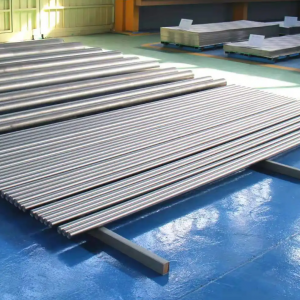

Inconel718/ UNS N07718 Pipe, Plate, Bar Professional Manufacturer

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings

Production Standards

|

Product |

ASTM |

|

Bars and Forgings |

B 637 |

|

Plate, Sheet and Strip |

B 670, B 906 |

|

Seamless pipes and fittings |

B 983 |

Chemical Composition

|

% |

Ni |

Fe |

Cr |

Mo |

C |

Mn |

Si |

P |

S |

Co |

Nb+Ta |

Ti |

Al |

Cu |

B |

|

Min |

50.0 |

|

17.0 |

2.80 |

|

|

|

|

|

|

4.75 |

0.65 |

0.20 |

|

|

|

Max |

55.0 |

21.0 |

3.30 |

0.08 |

0.35 |

0.35 |

0.015 |

0.015 |

1.00 |

5.50 |

1.15 |

0.80 |

0.30 |

0.006 |

Physical Properties

|

density |

8.23g/cm3 |

|

Melting |

1260-1335℃ |

Inconel 718 Features

Inconel 718 is a precipitation hardening nickel-based superalloy with excellent high temperature corrosion resistance. Commonly used in the aerospace industry, Inconel 718 offers elevated temperature mechanical strength as well as excellent ductility up to 704°C/1300F. It is non-magnetic in nature.

Nickel-based superalloy 718 has good resistance to oxidation and other types of corrosion in space jet engine and land-based gas turbine applications. It is the ideal material for applications requiring excellent resistance to creep and stress corrosion cracking (up to 982°C or 1800F). Alloy 718 provides complete protection against pitting and crevice corrosion in sulfides, chlorides, carbon dioxide and other harsh environments.

Inconel 718 has good comprehensive properties in the temperature range of -253 to 700 °C, the yield strength below 650 °C ranks first in deformed superalloys, and has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, and good performance. Processing performance, welding performance and long-term organizational stability, it can manufacture various parts with complex shapes, and has been widely used in the above temperature range in aerospace, nuclear energy, and petroleum industries.

Inconel 718 alloy is a precipitation hardening nickel-chromium-iron alloy containing niobium and molybdenum. It has high strength, good toughness and corrosion resistance in high and low temperature environment below 650℃. This state may be solution treated or precipitation hardened.

1. Easy to process

2. High tensile strength, fatigue strength, creep strength and rupture strength at 700℃

3. 1000℃ high oxidation resistance

4. Chemically stable at low temperature

5. Good welding performance

Inconel 718 Similar Grades

GH4169, GH169 (China), NC19FeNb (France), NiCr19Fe19Nb5, Mo3 (Germany), NA 51 (UK) Inconel718, UNS NO7718 (USA) NiCr19Nb5Mo3 (ISO)

Inconel718 Product Application Areas

Due to its high temperature strength at 700°C, excellent corrosion resistance and easy processability, it can be widely used in various high-demand occasions.

1. Steam turbine

2.Liquid fuel rocket

3.Cryogenic engineering

4.Acid environment

5.Nuclear Engineering