Hastelloy C-276/ AlloyC276/ UNS N10276 Professional Nickel Alloy Manufacturer

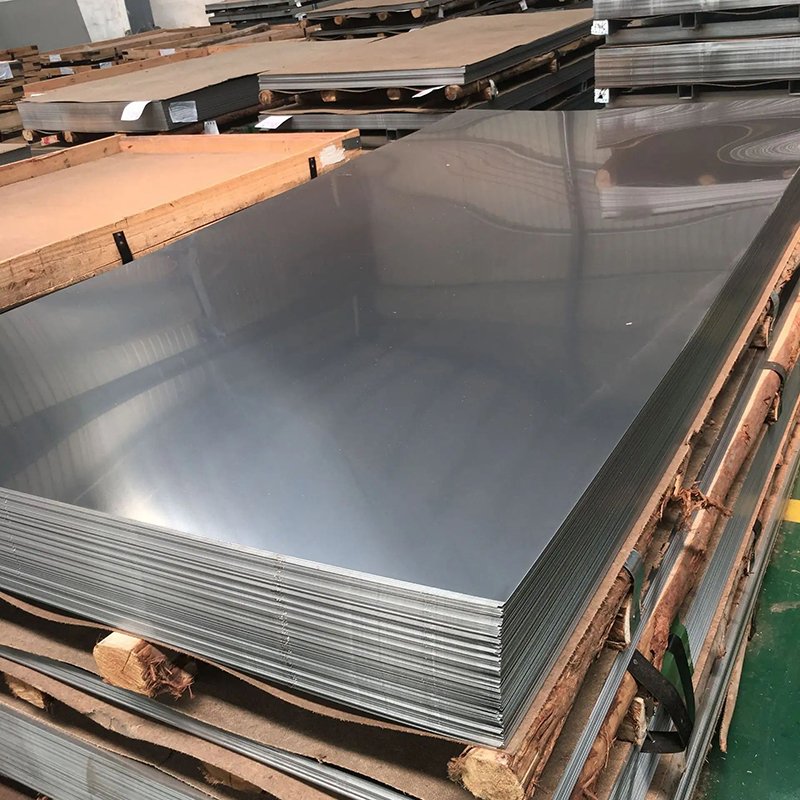

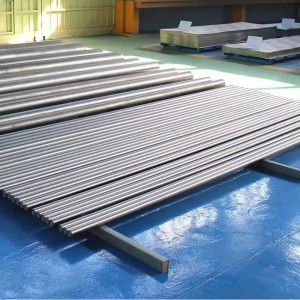

Available Products

seamless tube ,Plate,Rod,Forgings, Fasteners, strip,wire,Pipe Fittings

Production Standards

|

Products |

ASTM |

|

Bar |

B 574 |

|

Plate, sheet and strip |

B 575 |

|

Seamless pipes and fittings |

B 622 |

|

Welded nominal pipe |

B 619, B 775 |

|

Welded pipe |

B 626, B 751 |

|

Welded pipe fitting |

B 366 |

|

Forged or rolled pipe flanges and forged pipe fittings |

B 462 |

|

Billets and rods for forging |

B 472 |

|

Forgings |

B 564 |

Chemical Composition

|

% |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

P |

S |

V |

|

min |

|

20.0 |

12.5 |

2.0 |

2.5 |

|

|

|

|

|

|

|

|

max |

22.5 |

14.5 |

6.0 |

3.5 |

2.5 |

0.015 |

0.50 |

0.08 |

0.020 |

0.020 |

0.35 |

Physical Properties

|

Density |

8.69 g/cm3 |

|

Melting |

1325-1370℃ |

The alloy has excellent corrosion resistance to most corrosive media in oxidized and reduced states. Excellent resistance to pitting, crevice and stress corrosion cracking. The alloy is suitable for use in a variety of chemical process industries containing oxidizing and reducing media. The higher content of molybdenum and chromium makes the alloy resistant to the corrosion of chloride ions, and the tungsten element further improves its corrosion resistance. Hastelloy C-276 is one of the few materials that can resist the corrosion of moist chlorine, hypochlorite and chlorine dioxide solutions. iron and copper chloride).

Hastelloy C276 is a versatile nickel-molybdenum-chromium-tungsten alloy with excellent corrosion resistance and good machinability. Although it does have good oxidation resistance up to 1800°F, Hastelloy C276 is generally not recommended for use in high temperature environments.

Nickel alloy C-276 resists the formation of grain boundary precipitates in the heat-affected zone of welding, making it a candidate material for most chemical and petrochemical processing applications under welding conditions. HC276 is a nickel alloy with excellent resistance to reducing acids, sulfuric acid, hydrochloric acid, brine solutions, oxidizing chlorides and hot water.

Hastelloy C276 is also one of the few materials that is resistant to wet chlorine, hypochlorite and chlorine dioxide. This special nickel alloy has excellent resistance to crevice and stress corrosion cracking, as well as chloride pitting. Its low carbon content minimizes carbide precipitation during welding and maintains its excellent corrosion resistance. This means that C-276 can be easily fabricated by welding using methods similar to nickel-based alloys.

Hastelloyc-276 Application Scope Application Areas Are

C276 alloy has been widely used in chemical and petrochemical fields, such as components and catalytic systems in contact with chlorine-containing organic substances. The material is especially suitable for high temperature, inorganic acid and organic acid mixed with impurities (such as formic acid, acetic acid), seawater corrosion environment.

HASTELLOY C-276 has excellent resistance to a variety of chemical process environments, including thermally polluted inorganic acids, ferric and copper chlorides, solvents, chlorine and chlorine polluted organic and inorganic pollutants, dry chlorine, acetic anhydride, Formic and acetic acids, seawater and brine solutions, chlorine dioxide solutions and hypochlorite.

ASTM B622 ASME SB 622 N10276 Hastelloy C276 Other fields of application:

1. Digesters and bleaching agents used in the pulp and paper industry.

2. Absorption tower, reheater and fan in FGD system.

3. Equipment and components used in sour gas environment.

4. Acetic acid and anhydride reaction generator

5. Sulfuric acid cooling

6.MDI

7. Manufacture and processing of impure phosphoric acid.