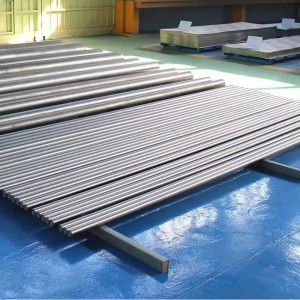

HastelloyB-3 / UNS N10675 Tube, Plate, Fittings, Forgings, Rod

Available Products

Seamless Tube, Plate, Rod, Forgings, Fasteners, Strip, Wire, Pipe Fittings

Production Standards

|

Products |

ASTM |

|

Bar |

B 335 |

|

Plate, sheet and strip |

B 333 |

|

Seamless pipes and fittings |

B 366 |

|

Welded nominal pipe |

B 619 |

|

Welded pipe |

B 626 |

|

Welded pipe fitting |

B 366 |

|

Forged or rolled pipe flanges and forged pipe fittings |

B 462 |

|

Billets and rods for forging |

B 472 |

|

Forgings |

B 564 |

Chemical Composition

| % | Ni | Cr | Mo | Fe | Ti | Co | C | Mn | Si | P | S | V | Ti | Cu | Nb |

| min | Balance | 1.0 | 27.0 | 1.0 | |||||||||||

| max | 3.0 | 32.0 | 3.0 | 0.2 | 3.0 | 0.01 | 3.0 | 0.1 | 0.030 | 0.010 | 0.2 | 0.2 | 0.2 | 0.2 |

Physical Properties

|

density |

9.22 g/cm3 |

|

Melting |

1330-1380℃ |

Hastelloy B-3 alloy is a new member of the family of nickel-molybdenum alloys, which has excellent corrosion resistance to hydrochloric acid at any temperature and concentration. At the same time, it also has good corrosion resistance to sulfuric acid, acetic acid, formic acid, phosphoric acid and other non-oxidizing media. Moreover, due to the adjustment of its chemical composition, its thermal stability has been greatly improved compared to the original Hastelloy B-2 alloy. Hastelloy B-3 alloy has high resistance to pitting corrosion, stress corrosion cracking, knife corrosion and corrosion in the heat affected zone of welding.

Hastelloy B-3 alloy is another nickel-based advanced alloy after B-2 alloy. It has a specially designed chemical composition to achieve a higher level of thermal stability than other Hastelloy alloys such as B-2 and has excellent resistance to pitting, crevice corrosion, stress corrosion, knife corrosion and thermal effects ability to corrode. Due to the improved thermal stability of the B-3 alloy, the problems encountered in the manufacture of parts like the B-2 alloy are reduced due to the reduced precipitation of harmful intermediate phases in the B-3 alloy trend. This provides higher ductility than B-2 alloys under thermal cycling conditions such as casting and welding.

This nickel-molybdenum alloy has excellent resistance to all concentrations of hydrochloric acid at ambient to elevated temperatures. It is also resistant to sulfuric, acetic, formic and phosphoric acids and other non-oxidizing media. B-3 also has excellent resistance to pitting and stress corrosion cracking.

Material Properties Of B-3 Alloy

Excellent resistance to hydrochloric acid at all concentrations and temperatures, resistance to sulfuric, acetic, formic and phosphoric acids and other non-oxidizing media Excellent resistance to pitting and stress corrosion cracking.

Typical Application Of Hastelloy B3

Hastelloy B series alloys are usually used in harsh and strong corrosive environments, and are widely used in chemical, petrochemical, energy and pollution control fields, especially in industries such as sulfuric acid, hydrochloric acid, phosphoric acid, and acetic acid, such as distillation and concentration of hydrochloric acid; low pressure Oxylated acetic acid (HAC); halogenated butyl rubber (HIIR); polyurethane raw materials and ethylbenzene alkylation production and other process equipment.

Due to the high price, the application of Hastelloy B series alloys is relatively concentrated, mainly in the production of acetic acid (oxo synthesis) and some sulfuric acid recovery systems, such as evaporators and dilute sulfuric acid storage tanks in acetic acid engineering.