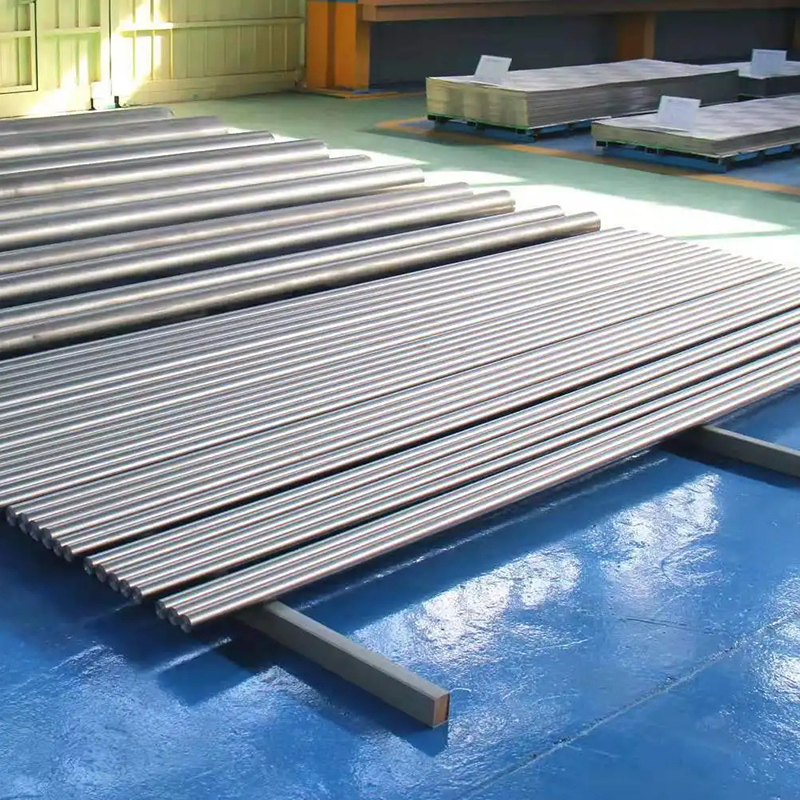

S32205/ S31803 Tube, Plate, Bar

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings.

Production Standards

| Product | ASTM |

| Bars, strips and profiles | A 276, A 484 |

| Plate, Sheet and Strip | A 240, A 480 |

| Seamless and Welded Pipes | A 790, A 999 |

| Seamless and Welded Pipe Fittings | A 789, A 1016 |

| Fittings | A 815, A 960 |

| Forged or rolled pipe flanges and forged fittings | A 182, A 961 |

| Forging billets and billets | A 314, A 484 |

Chemical Composition

|

% |

Fe |

Cr |

Ni |

Mo |

C |

Mn |

Si |

P |

S |

N |

|

Min |

Balance |

22.0 |

4.5 |

3.0 |

0.14 |

|||||

|

Max |

23.0 |

6.5 |

3.5 |

0.030 |

2.00 |

1.00 |

0.030 |

0.020 |

0.20 |

Physical Properties

| Density | 7.69 g/cm3 |

| Melting | 1385-1443℃ |

S32205 Material Properties

ASTM A240/A240M--01 Duplex stainless steel 2205 alloy is a duplex stainless steel composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy. It has high strength, good impact toughness and good overall and local stress corrosion resistance. The yield strength of 2205 duplex stainless steel is more than double that of ordinary austenitic stainless steel. This feature allows designers to reduce weight when designing products, making this alloy more affordable than 316 and 317L. This alloy is particularly suitable for use in the -50°F/+600°F temperature range. For applications outside this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.

Advantages of S32205 Duplex Steel

1.The yield strength is more than double that of ordinary austenitic stainless steel, and it has the necessary forming requirements.

Sufficient plasticity. The wall thickness of storage tanks or pressure vessels made of duplex stainless steel is 30-50% lower than that of commonly used austenite, which is conducive to reducing costs.

2.It has excellent resistance to stress corrosion cracking. Even the duplex stainless steel with the lowest alloy content has a higher resistance to stress corrosion cracking than austenitic stainless steel, especially in the environment containing chloride ions. Stress corrosion is a prominent problem that ordinary austenitic stainless steel is difficult to solve.

3.The corrosion resistance of the most commonly used 2205 duplex stainless steel in many media is better than that of ordinary 316L austenitic stainless steel, while the super duplex stainless steel has extremely high corrosion resistance, and in some media, such as acetic acid, formic acid It can even replace high-alloy austenitic stainless steel, and even corrosion-resistant alloys.

4. It has good local corrosion resistance. Compared with austenitic stainless steel with equivalent alloy content, its wear corrosion resistance and fatigue corrosion resistance are better than austenitic stainless steel.

5. The coefficient of linear expansion is lower than that of austenitic stainless steel, which is close to that of carbon steel. It is suitable for connecting with carbon steel and has important engineering significance, such as the production of composite plates or linings.

6. Whether under dynamic load or static load conditions, it has higher energy absorption capacity than austenitic stainless steel, which has obvious advantages for structural parts to cope with sudden accidents such as collision, explosion, etc., and has practical application value.

S32205 Material Application Areas

Pressure vessels, high-pressure storage tanks, high-pressure pipes, heat exchangers (chemical processing industry).

1.Oil and gas pipelines, heat exchanger fittings.

2.Sewage treatment system.

3.Pulp and paper industry classifiers, bleaching plants, storage and treatment systems.

4.Rotary shafts, press rolls, blades, impellers, etc. in high-strength and corrosion-resistant environments.

5.Cargo boxes for ships or trucks

6.Food processing equipment