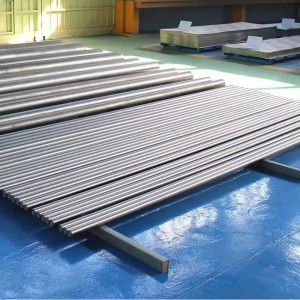

HastelloyG30/ UNS N06030/ AlloyG30 Seamless Pipe, Sheet, Bar Professional Manufacturer

Available Products

Seamless tube, Plate, Rod, Forgings, Fasteners, Pipe Fittings

Chemical Composition

|

% |

Ni |

Cr |

Mo |

Fe |

Cu |

W |

C |

Mn |

Si |

P |

S |

Co+Ta |

|

min |

balance |

28.0 |

4.0 |

13.0 |

1.0 |

1.5 |

|

|

|

|

|

0.3 |

|

max |

31.5 |

6.0 |

17.0 |

2.4 |

4.0 |

0.03 |

1.50 |

0.8 |

0.04 |

0.02 |

1.5 |

Physical properties

|

Density |

8.64 g/cm3 |

|

Melting |

1350-1400℃ |

Hastelloy G30 has a higher chromium content with the addition of cobalt and tungsten, which makes the G30 alloy perform better than most other iron-nickel-based corrosion-resistant alloys in industrial phosphoric acid and complex environments containing highly oxidizing acids. Compared with G3, 20 alloy and 625 alloy in phosphoric acid resistance, the performance is better than that of G3, 20 alloy and 625 alloy, the difference is 2-10 times, the performance in HIL acid is not very good, and it has usable corrosion resistance in concentrated sulfuric acid below 50 degrees, in nitric acid, mixed It has excellent corrosion resistance in acid. Due to the high chromium content, the main corrosion resistance characteristic of G30 is that the performance of H3PO4 containing Cl- and F- is significantly better than that of Hastelloy G3 alloy. It also has excellent corrosion resistance in nitric acid + hydrofluoric acid, sulfuric acid + hydrofluoric acid. The alloy can be used for evaporators in the industrial production of wet-process phosphoric acid, equipment and components for stainless steel pickling HNO3+HF mixed acid, and can also be used for corrosion-resistant devices in nuclear fuel production.

Application Fields

Analysis Therefore, the alloy is a high-chromium alloy, so it has excellent corrosion resistance in the strong acid corrosion medium containing F, CL and other oxidative impurities, mainly using wet-process phosphoric acid production and processing and nitric acid hydrofluoric acid pickling equipment and parts . This alloy has corrosion resistance, excellent processing performance and high strength, so it is also an optional structural steel for acid oil and gas wells.

Phosphoric acid production, sulfuric acid production, nitric acid production, nuclear waste treatment, nuclear fuel recovery, pickling operations, petrochemicals, fertilizer production, pesticide production, gold mining, deep sea sour gas well casings and liners and well tubing, sour gas transmission lines .

Guojin Company Hastelloy Series

B series: B→B-2(00Ni70Mo28)→B-3

C series: C→C-276(00Cr16Mo16W4)→C-4(00Cr16Mo16)→C-22(00Cr22Mo13W3)→C-2000(00Cr20Mo16)

G series: G→G-3 (00Cr22Ni48Mo7Cu)→G-30(00Cr30Ni48Mo7Cu)

The most widely used are the second generation materials N10665(B-2), N10276(C-276), N06022(C-22), N06455(C-4) and N06985(G-3)