Inconel 600 is a nickel-chromium-iron alloy that exhibits good corrosion resistance, oxidation resistance, and high strength at elevated temperatures. Inconel 600 is highly resistant to chloride ion stress corrosion cracking due to its high nickel content. Age hardening is not required since Inconel 600 is hardened and strengthened only by cold working. Inconel 600 can perform in temperatures down to 700°F (370°C).

Industry supplied

Chemical processing, thermal processing, nuclear energy and aerospace.

Nominal composition

Chromium: 14.0 – 17.0

Iron: 6.0 – 10.0

Manganese: 1.0 max

Nickel: 72 minutes

Copper: 0.5 max

Silicon: max 0.5

C: 0.15 max

S: 0.015 max

physical properties

Density: 0.306 lb/in3, (8.47 g/cm3)

Elastic modulus (E):

At 70°F (20°C): 31.1 x 103 ksi (214 GPa)

Modulus of Rigidity (G):

At 70°F (20°C): 11.7 x 103 ksi (81.0 GPa)

Coefficient of expansion:

7.9 in/in-°F (70°F to 600°F)

14.2 m/m-°C (20°C to 300°C)

Resistivity: 40.6 Ω in (130 Ω.cm)

Thermal Conductivity: 103 BTU in/ft 2h-°F, (14.9 W/m-K)

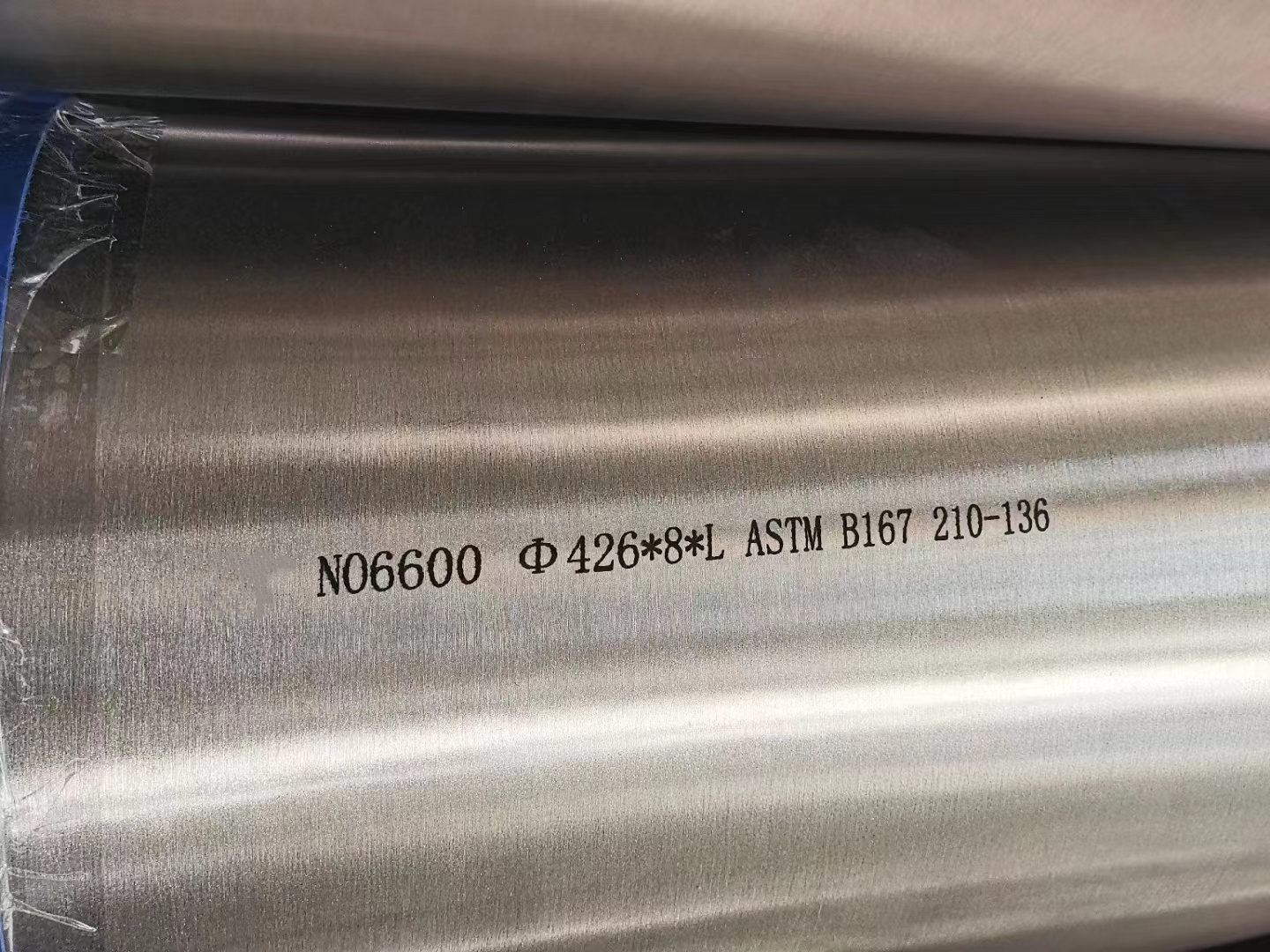

Applicable specifications

Wire and Bar: AMS 5665, AMS 5687, ASTM B166.

Typical Mechanical Properties – Spring Applications

annealing

Heat Treatment: 1925°F (1050°C)

Tensile Strength: 80 – 110 ksi; (552-758 MPa)

Recommended Operating Conditions: -300°F to 700°F (-184°C to 370°C)

Tensile Strength: 160 – 200 ksi; (1103 – 1379 MPa)

Recommended Operating Conditions: -300°F to 700°F (-184°C to 370°C)